Photo by Tiffany

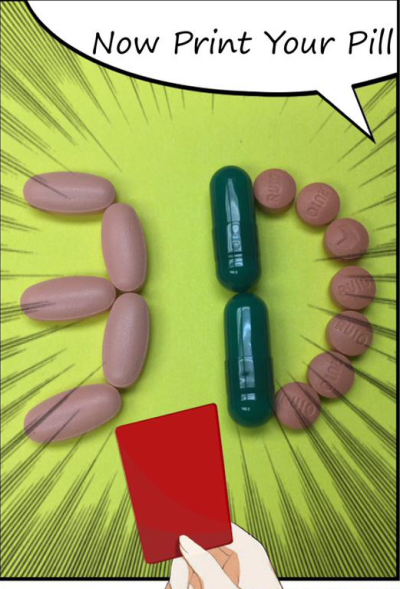

There’s a new game changer on the horizon and for those of you who are fans of Star Trek, it may sound an awful lot like a replicator. 3D printing has been around in some form since the 1980’s, but in recent years, the technology has been breaking ground with advancements in all things from medicine to art – and everything in between. It’s now poised to revolutionize a number of markets, including the pharmaceutical industry.

Aprecia Pharmaceuticals’ new 3D printed drug, Spritam, has been FDA approved to treat seizures and is expected to hit the market sometime in early 2016. According to Aprecia, the 3D printing process they used was originally developed at MIT and allows them to get an incredible amount of accuracy in the delivery system of up to 1,000 mg per tablet.

According to the manufacturer, the tablet has a "porous formulation" that dissolves with in the tiniest sip of liquid, making it super convenient for people and children who have trouble taking pills. If the online videos of it are any verification, I’ve watched the tablet dissolve at an astonishingly fast rate.

One of the more remarkable aspects of the 3D printing process is that it allows layers of medication to be packaged more tightly in precise dosages. In turn this means 3D-printed pills could be custom-ordered based on specific patient needs, rather than on a one-drug-fits-all approach. A visit to the pharmacy may soon involve inputting your body details such as height and weight to custom tailor a pill that will work with your own body chemistry. For kids, this could mean being able to pick colors, shapes, and perhaps even favorite cartoon characters (though I’m a big proponent that medicine should look like medicine so small children won’t accidentally ingest something they shouldn’t!).

In some ways, the best part is instead of storing one-size-fits-all packets of tablets, pharmacists will be able to make everything for you right on site like back in the days of apothecaries. This means having reels of filaments of the base product so they can customize the dose and shape of tablet to our individual needs.

As with most processes, the largest downside to the 3DP technology lends itself to human error. In the traditional manufacturing, there is a 4-5% margin of error and according to many statistics this number is unlikely to change with the new technology. Humans are still in charge of putting in the correct blueprints, the right base material reel, and checking over the drugs before they are handed out. At any one of those junctures, things could go wrong. However, as technology gets better, hypothetically, so will the technology that double-checks our work – thus reducing the human error margin.

Some are concerned about the ability to hack a blueprint, or gain access to the drugs from home, possibly illegally. However, perhaps it’s just me, but I see beyond the immediate future to a point where printing our prescriptions from home will be an everyday norm. Perhaps it’s the science fiction lover in me, but it makes sense.

Whether you love or hate the idea of 3DP technology and its revolutionary approach, one thing is certain; it’s here to stay. Time to buckle up and embrace the future, people, because it’s here.

###

Carissa Andrews is a passionate author and freelancer from Minnesota with a focus in creative writing.